Week 5

Date: 10/11/18 Time: 4:30-6:30pm

Week #: 5

Quick Summary:

- We replaced the gearing system for the arm with a chain and sprocket system.

- We added a “tongue” to the arm in order to keep the minerals from falling out of the bucket on their way to the lander.

- We made a vacuum that lifts minerals off the ground.

- The alternated big gears and little sprockets that make up the vacuum are causing the minerals to drift to one side and not go into the bucket.

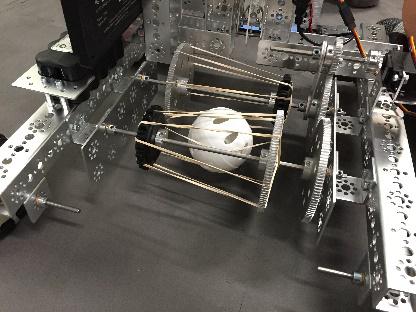

What We Accomplished: We added a chain and sprocket system to lift the arm. It is better than the gears because it doesn’t strip and is stronger. The motor is at the bottom of the robot and is connected by chains to a big gear at the top of the arm. When the motor turns, the chains pull on the gear and rotate it, making the axle inside it turn and therefore lift or lower the arm. We also added more support to the base by connecting the sides of the base in the middle. The most noticeable change that we made is the vacuum made with gears and rubber bands located in the middle of the robot. We alternated the big gears and the little black sprockets on the system is because we found it easier to pick the minerals up off the ground; the large gears helped the rubber bands get closer to the ground. We couldn’t put all large gears, however, because we didn’t have enough room between them, therefore causing the gears to mesh and allow no room for the rubber bands. Three rubber bands above the vacuum is used to push the minerals into the rubber bands and move them along toward the bucket. We solved the problem of the falling minerals by adding a “tongue” to the arm which supported them on the journey to the hopper.

Our Problems: Because the sprocket and gear system is off to the side, and it takes a lot of force to lift the arm, the arm is getting bent toward the side where the sprocket and chains are. The alternated gears and sprockets cause a problem. Because one side is lower, the minerals tend to drift toward that side and not go straight into the bucket on the arm. This makes the minerals not drop right into the bucket, which is positioned at the front of the robot and lined up in to middle of the rubber bands. And sometimes the vacuum gets jammed. A servo motor makes the sprockets turn, but the axle coming off the servo isn’t supported very well. This makes the vacuum weak and is easy to stop if a mineral is stuck. The rubber bands above the vacuum don’t work very well because it causes too much friction against the minerals, causing the process to be slow. The angle on the end of the tongue makes it so that when the arm is all the way up above the hopper, the minerals just roll off.